cases

- Meeting Reservation Tablet

- Advertising Display Tablet

- Restaurant Ordering Tablet

- Stand By Me TV(Big Tablet)

- Smart Home Tablet

- Medical Monitoring Tablet

- Industrial Tablet

- Rugged Tablet

Have any questions?

Please feel free to contactus. We will get back to you as soon as.

+86-13501581295 +86-13501581295 [email protected]

Manufacturing Case Study: Industrial Android All-in-One Panel Enhances Shop-Floor Visibility

As manufacturers push toward higher transparency, digital integration, and agile production, many factories still struggle with delayed information flow, unclear equipment status, and manual data collection that slows decision-making. Traditional paper-based reporting and manual inspections often lead to inconsistencies, making it difficult for managers to maintain real-time awareness of what’s happening on the shop floor.

A machining company expanding its production lines faced the same issues. With multiple workstations and a wide range of equipment types, the team found it increasingly difficult to track real-time status, record accurate process data, and identify abnormalities quickly enough to prevent downtime. To support their growth and improve operational visibility, the company began exploring a more efficient, data-driven management approach.

To solve these challenges, the company deployed a set of 10.1-inch Android-based HMI industrial all-in-one panels across the production line. These devices were integrated directly with their Manufacturing Execution System (MES), allowing operators, equipment, and management teams to share real-time information—thereby transforming traditional workflows into a transparent, automated, and collaborative environment.

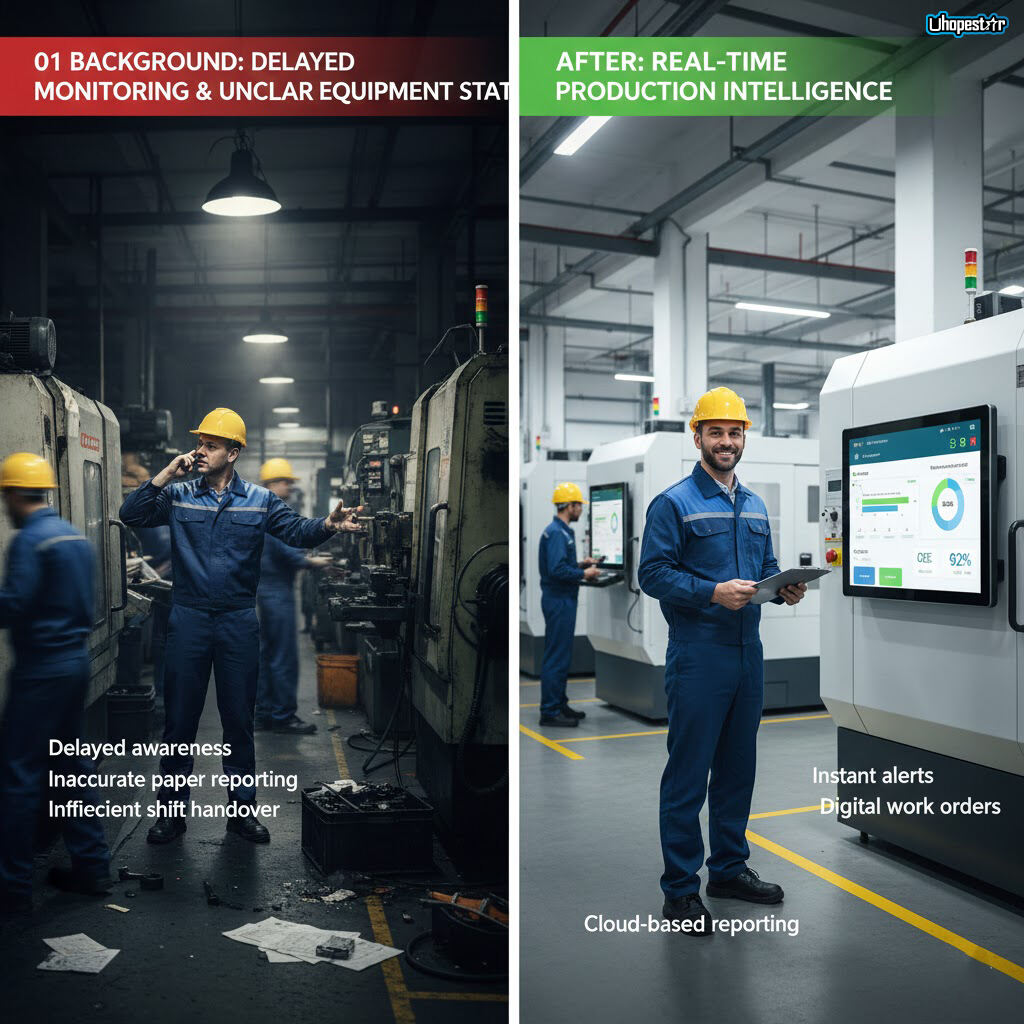

01 Background: Delayed Monitoring and Unclear Equipment Status

Before the upgrade, processes on the shop floor relied heavily on manual monitoring. Supervisors needed to walk through the workshop repeatedly to check equipment status, progress on work orders, and potential machine downtime. Because information was recorded manually and reported verbally, delays and errors were common.

During an internal assessment, the company identified several key issues:

-

Delayed awareness of abnormalities: Machine stoppages or quality issues often took 10–20 minutes to reach the supervisor.

-

Inaccurate paper-based reporting: Complex workflows made handwritten records prone to mistakes or missing data.

-

Inefficient handover between shifts: Incomplete information increased the risk of duplicated work or incorrect task sequencing.

-

Lack of real-time production metrics: Managers couldn’t access up-to-date output, utilization rates, or trend data.

These inefficiencies not only slowed production but also affected quality tracking, resource planning, and equipment maintenance scheduling. The company needed a system that could centralize information and deliver real-time feedback directly at each workstation.

02 Solution: Deploying 10.1-Inch Android HMI Panels Integrated With the MES

To address these challenges, the company installed 10.1-inch industrial Android panels at every critical workstation. Designed for industrial environments, the devices feature a metal housing, stable performance for 24/7 operation, and a responsive touchscreen suitable for dusty or high-use areas.

The implementation included the following key elements:

-

Real-time equipment status display

Each panel connects to the MES via Ethernet, showing machine running status, output quantities, stop reasons, and processing progress in real time. -

Digital work order management

Operators can view updated work instructions, parameter notes, and process steps directly on the screen, eliminating the need for paper documents. -

Instant abnormality reporting

When the equipment detects an error or stops unexpectedly, the panel sends an alert to the MES immediately, allowing supervisors to respond quickly. -

Simple and accurate data feedback

Operators input production data directly into the panel. The MES automatically aggregates and records all information, reducing manual errors. -

Remote monitoring and collaboration

Management teams can view production dashboards from the control room or remote office, supporting multi-line and multi-factory coordination.

The compact form factor of the 10.1-inch panel makes it easy to install on machine frames, wall mounts, or workstation stands, ensuring operators can access information comfortably without changing their workflow.

03 Results: Real-Time Visibility, Faster Alerts, and Better Collaboration

After three months of system operation, the factory observed significant improvements in workflow efficiency, production transparency, and communication. Key results included:

● Clearer and faster production monitoring

Operators gained a direct view of machine status, task progress, and required parameters. Managers could access real-time dashboards, eliminating the need for constant on-site inspections. Information that once took minutes or hours to reach the management team became immediately available.

● Reduced downtime through instant abnormal alerts

Unexpected issues—such as tool wear, material shortages, or process deviations—triggered automatic alerts. This rapid response helped minimize unplanned downtime, improving equipment utilization and overall production stability.

● Improved accuracy with digital workflows

By eliminating handwritten records, the factory significantly reduced data inconsistencies. Work orders were transmitted precisely, shift handovers were smoother, and historical data became easier to track for audits and quality control.

● Remote coordination and simplified management

Supervisors now oversee multiple lines without physically walking through the workshop. Remote access to production performance, machine health data, and trend analytics supports faster decision-making and more efficient resource allocation.

By integrating 10.1-inch Android industrial HMI panels with their MES system, the company successfully transitioned from a manual, paper-based workflow to a real-time, fully visible production environment. This upgrade not only enhances current operational efficiency but also lays a strong foundation for future digital initiatives such as predictive maintenance, production optimization, and multi-factory coordination.